FOSHAN CICHENG CHEMICAL MACHINERY CO.,LTD

FOSHAN CICHENG CHEMICAL MACHINERY CO.,LTD

- …

FOSHAN CICHENG CHEMICAL MACHINERY CO.,LTD

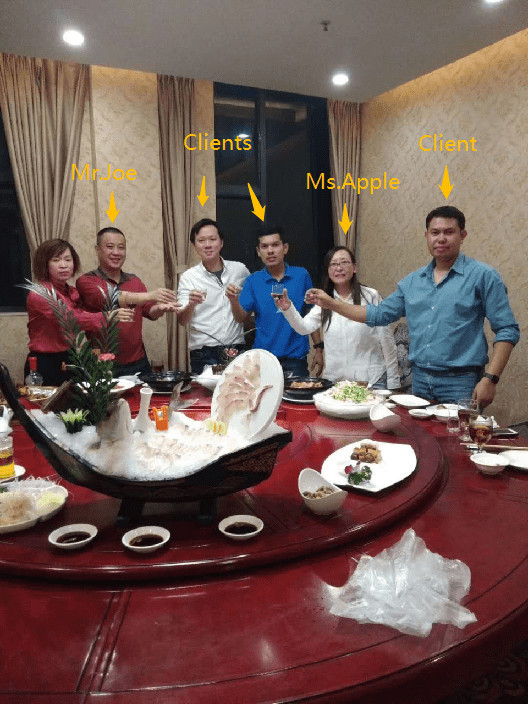

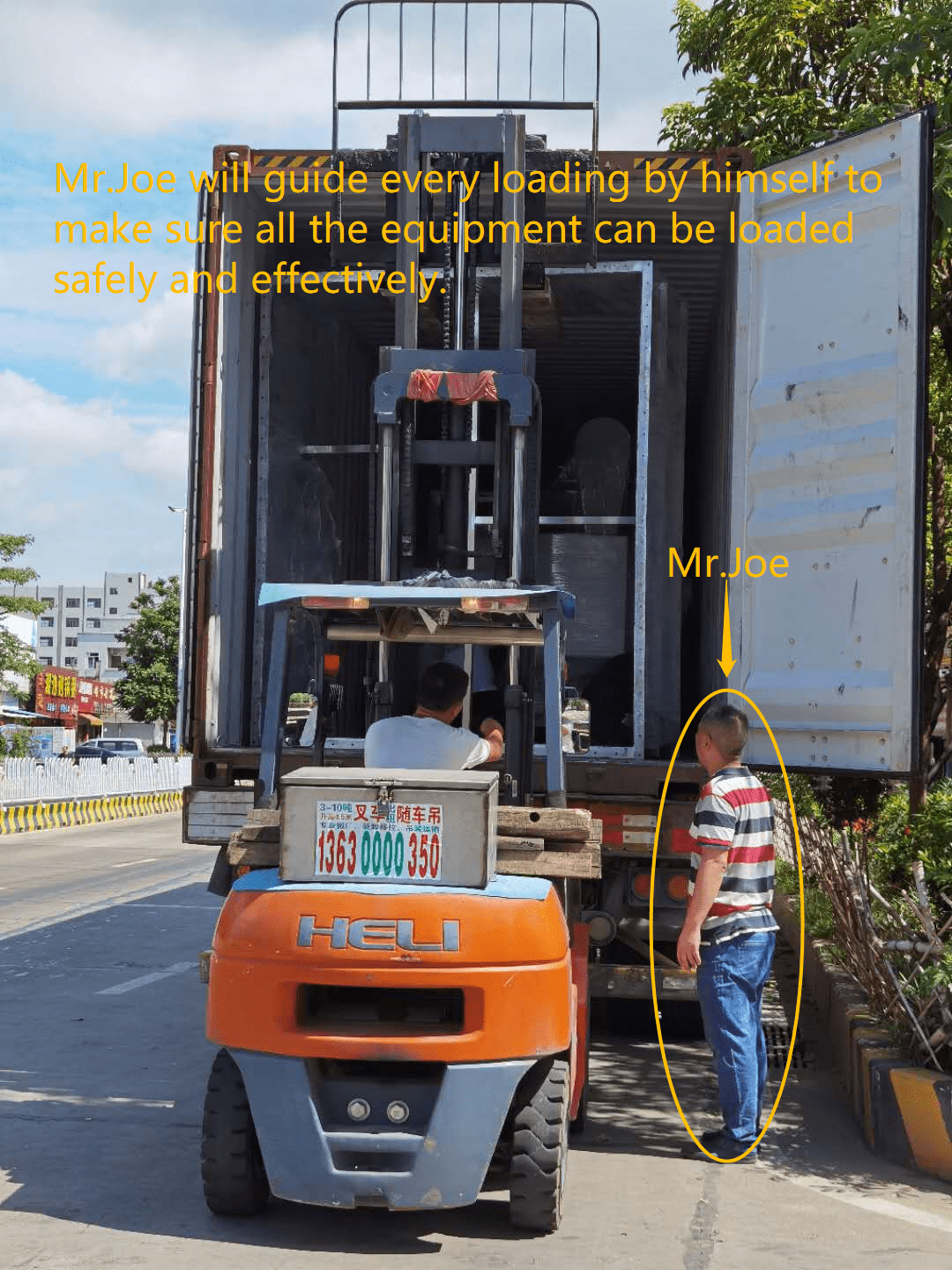

FOSHAN CICHENG CHEMICAL MACHINERY CO.,LTD (hereinafter referred to Cicheng Machinery) is owned by Mr.Zhou Fawei(Mr.Joe), located in Foshan City, Guangdong Province, China.It is a vibrant and rapidly changing city and an important manufacturing base in China.Relying on the advantages of Guangdong's huge manufacturing industry, Nanhai Cicheng has made remarkable achievements with enterprising spirit and vigorous development.

Cicheng Machinery is a comprehensive technology company which designs, produces and sells chemical equipment and related chemicals.Mr. Joe, the founder of the company, has been engaged in PVC stabilizer industry for many years and has rich experience in r&d of PVC stabilizer technology.The lead stearate,calcium stearate,zinc stearate equipment and compound stabilizer equipment with dry method developed by Mr. Joe has provided services for many domestic stabilizer manufacturers and received unanimous praise.The stabilizer production line produced by our company is a complete set of production line, which is the first specialized company in China that can provide the complete set of stabilizer production line services.

We can supply the following production lines:

1. Lead base stabilizer production line(plant\machine\equipment)

2. Calcium zinc stabilizer production line(ca zn stabilizer ) (plant\machine\equipment)

3. stearate metal salt production line

3.1 calcium stearate production line(plant\machine\equipment)

3.2 magnesium stearate production line(plant\machine\equipment)

3.3 barium stearate production line(plant\machine\equipment)

3.4 zinc stearate production line(plant\machine\equipment)

3.5 lead stearate production line(plant\machine\equipment)

4. Tribasic lead sulfate(TBLS) dibasic lead phosphite(DBLP)(plant\machine\equipment)

5. Litharge production line(lead oxide,Pb oxide,PbO,yellow lead)(plant\machine\equipment)

6. Hydrotalcite production line (plant\machine\equipment)

7. PE wax purifying and mixing production line

8.Fully Automatic PVC Stabilizer Production Line (plant\machine\equipment)

Better day by day,better year by year.Relying on the abundant resources in PVC stabilizer industry, the company adopts diversified development strategy, takes PVC stabilizer equipment as the core, develops the upstream and downstream industries and the surrounding industries of PVC stabilizer equipment, strives to develop the international market, and makes great achievements.Our company supply equipment and service to many China's domestic customers such as Shandong Sanyi,Hebei Jingxin and other large stabilizer industry leading enterprises.The company's equipment has been exported to southeast Asia and the Middle East.International customers praise highly of our equipment and after-sales service.

Zhou Fawei Plant has always adhered to the principle of "strong contract, good faith, good service and win-win development", and established and developed extensive cooperative relations with domestic and international production enterprises and trading companies.In the journey to the 21st century, the company will be market-oriented, trade-led, assets-linked, industry-backed, willing to cooperate wholeheartedly with colleagues from all walks of life at home and abroad, become a multi-functional, all-around, international operating entities.

OUR ADVANTAGES

Mr.Zhou Fawei ,the owner of our company,is a famous engineer of chemical and machinery in PVC stabilizer industry.He keeps good relations with most of PVC stabilizer owners and engineers.So our company has good resources and latest techniques in PVC stabilizer industry.

In recent years, the company vigorously expands the international market, the production line has been sold to southeast Asia and gained the customer’s praise.

After decades of unremitting efforts, our company has made outstanding achievements in China's PVC stabilizer industry.

80 % of PVC stabilizer plants in China bought production lined from our company.

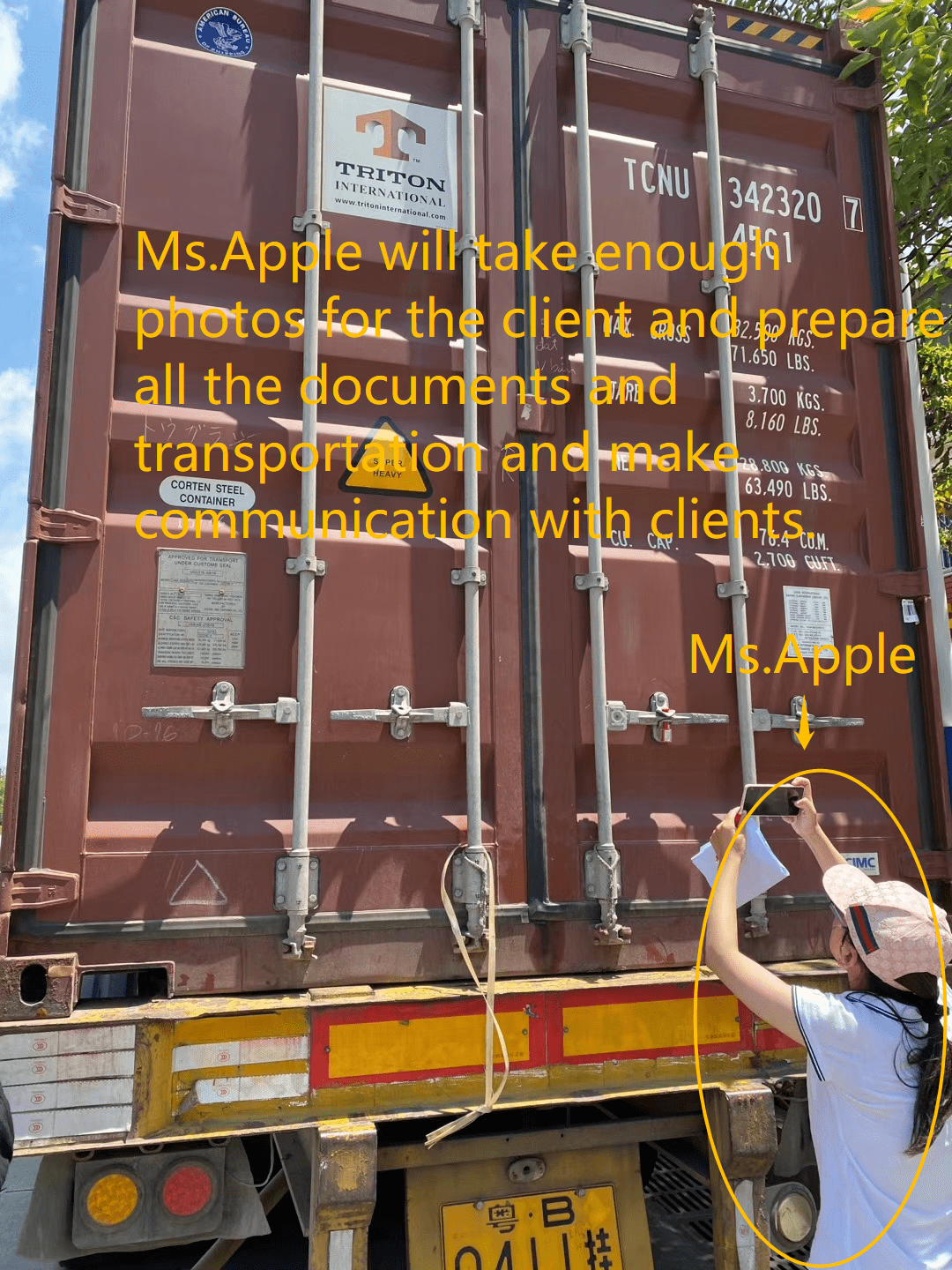

Our company can supply customized PVC stabilizer production line for your company according to your actual needs, and provide one-stop installation guidance and production guidance service.

PRODUCTION LINES

1.Lead stearate production line,zinc stearate production line,lead base stabilizer production line

It is feasible to produce lead stearate and lead base stabilizer together with the same line.It is acceptable to add stearate acid,PbO for making lead stearate and add PbO,stearate aicd,TBLS, DBLP, lubricant, etc. for making lead base stabilizer.

Actually,it is the same line to make lead base stabilizer (or lead stearate) and zinc stearate.But because of the toxicity of lead,it is not acceptable to produce lead base stabilizer (or lead stearate)and zinc stearate with the same line.So in order to make lead base stabilizer (or lead stearate) and zinc stearate,it is suggested to use the same two lines for making lead base stabilizer (or lead stearate ) and zinc stearate respectively.

We can supply formula technical production instruction service.

The production line is customized according to the client’s requirement.

The product form is flake.If powder form is required,please inform in advance.

Optional heating mode: steam heating,electric heating or conduction oil heating.

2.Production Line for Ca Zn Stabilizer

The line chooses colter mixer instead of ribbon mixer for reaction.Colter mixer is suitable for both dry-type mixing and wet-type mixing.Ribbon mixer is just suitable for dry-type mixing.Because when making ca zn stabilizer,it is required to add lubricant for mixing,it is better to use colter mixer.

We can supply formula technical production instruction service.

The production line is customized according to the client’s requirement.

The product form is powder.

Mixing mode: cold mixing.

3.Production Line for Calcium Stearate, Magnesium Stearate or Barium Stearate

It is feasible to produce calcium stearate and magnesium stearate together with the same line.

When switching production, please pay attention to cleaning the machine.If conditions permit, it is best to produce one kind of metal stearate with one line.

Actually,it is the same line to make calcium stearate,magnesium stearate and barium stearate.But because of the toxicity of barium,it is not acceptable to produce calcium stearate (or magnesium stearate)and barium stearate with the same line.So in order to make calcium stearate(or magnesium stearate) and barium stearate,it is suggested to use the same two lines for making barium stearate and calcium stearate (or magnesium stearate) respectively.

We can supply formula technical production instruction service.

The production line is customized according to the client’s requirement.

The product form is powder.

Optional heating mode: steam heating,electric heating or conduction oil heating

4.Production Line for TBLS,DBLP

The line is suitable for producing tribasic lead sulfate(TBLS),dibasic lead phosphite(DBLP).

If it is required to produce TBLS and DBLP together,it is better to buy 2 of the same lines.

When making production,the reaction will take water as the medium in the production line.It will produce much polluted water .It is necessary for the client to set up water treatment system.

We can supply formula technical production instruction service.

The production line is customized according to the client’s requirement.

The product form is powder.

Optional heating mode: steam heating,electric heating

5.Production Line for Litharge

The production line is suitable for the technical production from lead ingot to lead dioxide.The materials go through litharge sintering furnace second oxidized into qualified litharge powder.

The whole process is :lead ingot conveyor -smelting furnace-Barton furnace -filter -continuous oxide furnace-packing .

We can supply formula technical production instruction service.

The production line is customized according to the client’s requirement.

The product form is powder.

Optional heating mode: electric heating ,gas heating

6.Production Line for hydrotalcite

7.PE wax purifying and mixing production line

PE wax purifying and mixing production line is for reaction with reactor heating and mixing to purify the PE wax and produce composite formula PE wax . It can produce low viscosity and low melting point composite formula PE wax with raw materials of low molecular polyethylene or high viscosity and high melting point of PE wax . It can be applied into PVC products.

Convert ratio:low molecular polyethylene → PE wax:86%

CLIENTS

1.China clients

Shenzhen Aimsea Industries Co.,LTD

Shandong Sanyi Chemical (China)

Guangdong Bolison (China)

CHNV(China)

Guangdong Sunvo New Materials

Hebei Jingxin(Now named: Xiongfa Technology)

Belike chemical co.,ltd

Hunan Zhengqi Tongyuan Technology Co.,Ltd

Hunan Shuikoushan Joint Development New Materials Co.,Ltd

2.Abroad clientsEvergreen chemical ThailandPrior&Power IndustryTuantsuki VietnamCONTACT

FOSHAN CICHENG CHEMICAL MACHINERY CO.,LTD

Address: Sanshui District,Foshan City,Guangdong Province,China

Contact Person:Ms.Apple Wu

Wechat/whatsapp/mobile:+86-15104191037

Spype: apple830730

Email:15104191037@139.com